|

|

|

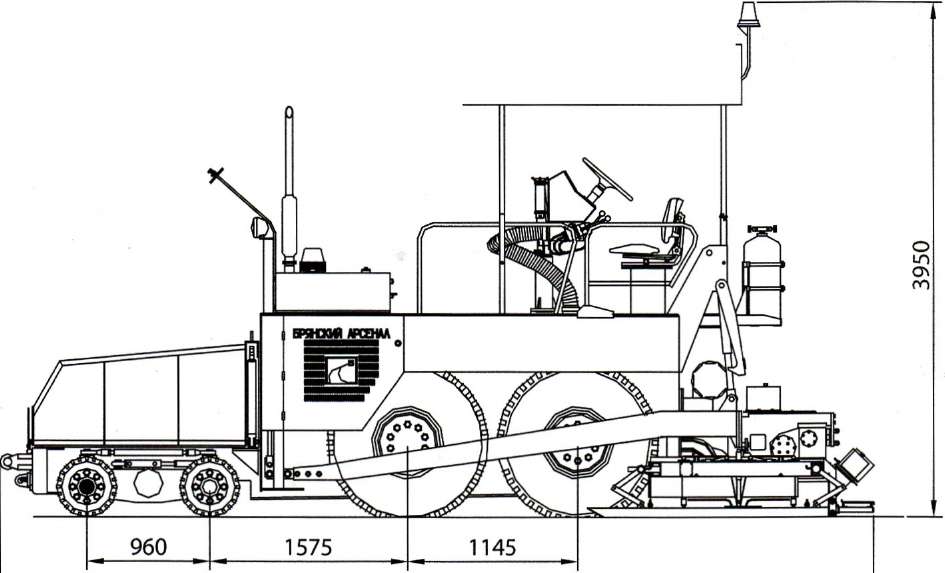

Asphalt Paver ASF-K-3-02

TECHNICAL SPECIFICATIONS

Productivity, t/h|

up to 500 |

|

Width of paving, m basic |

2,5...4,5(stepless) |

|

with replaceable fusions |

up to 6,5 |

|

Thickness of paving, mm |

up to 6,5 |

|

Batcher capacity with a tunnel, t |

10 |

|

SPEED: |

|

Working speed, m/min |

up to 20 |

|

Transport speed, km/h |

up to 16 |

|

Rammings beams beat frequency,Hz |

up to 30 |

|

Vibroplate vibration frequency, Hz |

up to 60 |

|

General dimensions,mm: |

|

Length |

6 700 |

|

Width: In working position |

3 120 |

|

Width: In transport position |

2 530 without flanges |

|

Height: With raised awning |

3 950 |

|

Height: With lowered awning |

3 100 |

|

Weight, kg |

16 500 |

|

ASPHALT PAVER UNIT STRUCTURE |

|

Engine Type |

diesel |

|

Model |

D 260.1-112 |

|

Power, kwt |

114 |

- To improve the operator working conditions, the asphalt paver is fitted with a rotary control panel, allowing to operate the machine from any machine side.

- The asphalt paver serial is fitted with control-diagnostic system supervising 15 parameters of hydrosystem and the engine.

- For maintenance of high purity of the working liquid of hydrosystem all pipelines are made of stainless steel.

- As power hydraulic equipment on the asphalt paver the import hydroequipment is established.

- The tool of asphalt paver ASF-K-3-02 is executed on telescopic cylinders, with "rigidity" of the tool providing the greatest possible accuracy of asphalt-concrete mixture paving.

- Reversible feeders and auger have a separate onboard drive. The feeder drive are controlled, and the auger drive are with discrete electro controll and function manually as well as automatically.

- The driving mechanism of asphalt paver is fitted with the adjustable hydropump and the hydroengine so as to make optimal speed selection easier for the operator.

- Additional equipment: automatic system used for control of asphalt smoothing platform position, gas heating system for asphalt smoothing platform, replaceable fusions.

|

|

|